Electroless Nickel Papers

Ron Duncan served as Vice President of Palm International, Inc., where he led the company’s technical and educational initiatives. Prior to joining Palm, he was Director of Research at Elnic, Inc., focusing on electroless nickel formulation and materials research.

Before entering the metal finishing industry, Ron spent 12 years in the oil sector with Exxon and Caltex Petroleum Corporations, tackling materials and corrosion challenges. His work took him across the globe—including the United States, Middle East, Europe, South America, and Africa—where he developed a reputation for his deep expertise and practical problem-solving.

Ron held a BE in Mechanical and Metallurgical Engineering from Vanderbilt University. He was a Registered Professional Engineer and a certified Corrosion Specialist through NACE. A leader in technical standards, he chaired NACE task groups T-1G-19 and T-6A-53, contributing to authoritative reports on electroless nickel and other metallic coatings. He also served on the AESF’s Electroless Committee.

Throughout his distinguished career, Ron authored more than fifty technical papers on corrosion, coatings, and electroless nickel. His work appeared in Materials Performance, Plating and Surface Finishing, Metals Progress, Products Finishing, and Finishers Management, as well as in numerous industry conferences. He was the principal author of the electroless nickel chapter in Volume 5 of the Metals Handbook and was honored with the AESF Gold Medal in 1996 for the best paper published in Plating and Surface Finishing.

Ron also directed the Electroless Nickel School, a comprehensive four-day seminar presented by Palm, which educated professionals in all aspects of electroless nickel technology.

Ron Duncan passed away on December 15, 2006. He is deeply missed by his family, colleagues, and the broader surface finishing community. His legacy of innovation, mentorship, and integrity continues to inspire all who had the privilege of working with him.

Electroless Nickel: A Functional Solution for Industry's Problems

This paper will describe how electroless nickel coatings are applied and the unique structure and properties of the deposits. It will also describe some important and interesting applications of the coating.

Read

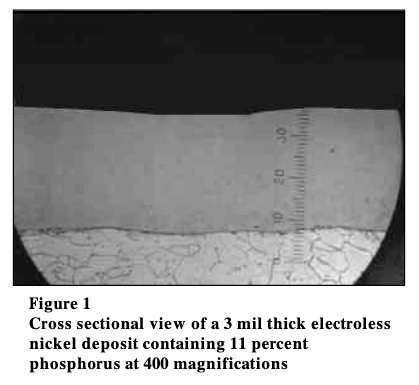

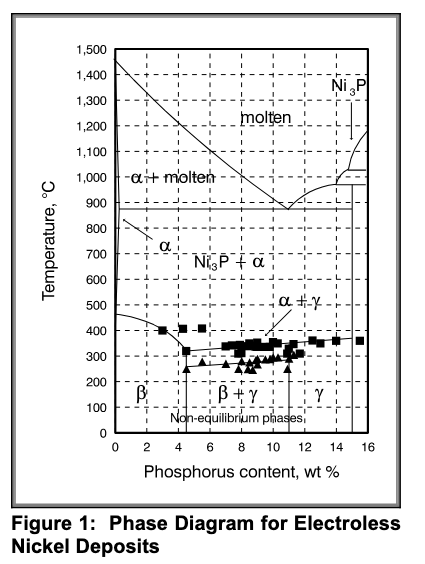

THE EFFECT OF METALLURGICAL STRUCTURE ON THE PROPERTIES OF ELECTROLESS NICKEL COATINGS

This paper describes the effect that composition and structure have on the properties of electroless nickel coatings. The internal stress, melting point, density, resistivity, magnetic response, strength and ductility, hardness and wear resistance, porosity, corrosion resistance and passivity of different coatings are described.

Read

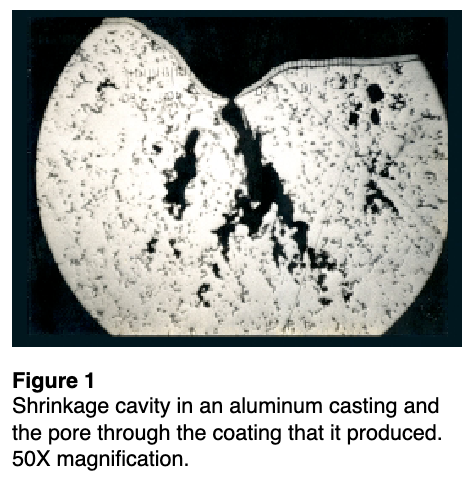

The Effect of the Substrate on Defects In Electroless Nickel Coatings

This paper explains how the substrate’s alloy, forming, mechanical finishing, and handling can lead to defects in the applied coating. It will also suggest techniques that can be used to help avoid some defects and failures.

Read

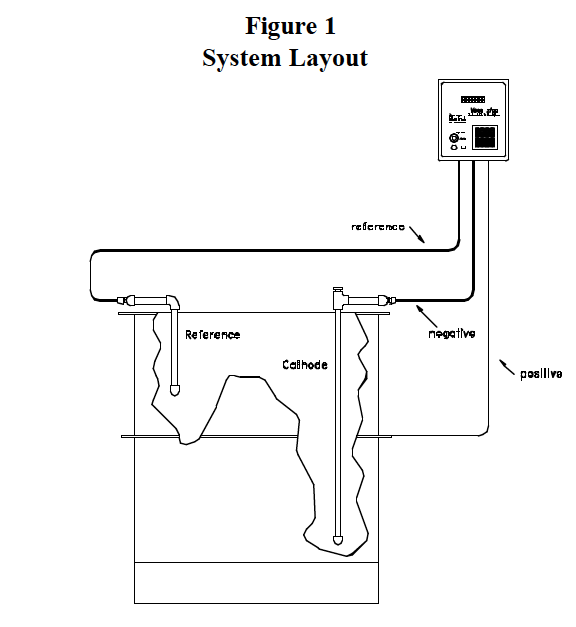

ANODIC PASSIVATION OF STAINLESS STEEL ELECTROLESS NICKEL TANKS

This paper describes this system and its theory of operation. Several case histories showing the system's value are also presented, along with the economic justifications for its use.

Read

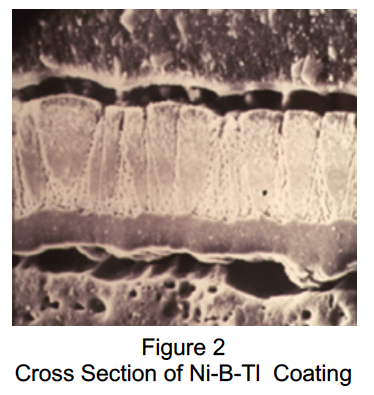

The Properties and Structure of Electroless Nickel-Boron Coatings

This paper describes the properties of electroless nickel coatings reduced with boron compounds and how they vary with changes in deposit composition. The effect of composition on the metallurgical structure of the coating is also described and compared with that of nickel-phosphorus alloys.

Read

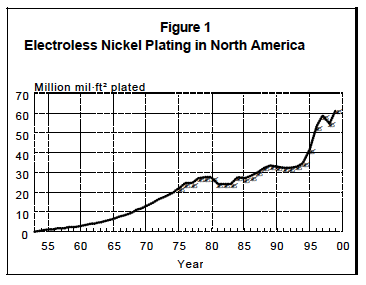

Electroless Nickel: Past, Present And Future

Note: While this paper is over 25 years old it still contains good information.

This paper describes the evolution of electroless nickel and how the present industry grew from this

process. The state of today's market, including its size, the types of baths used, and the types of the

parts and substrates plated, is also discussed. In addition, some thoughts on the future direction of

the industry are provided.

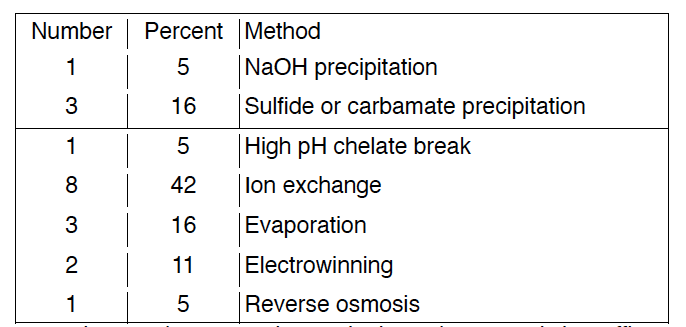

WASTE TREATMENT PRACTICES IN THE ELECTROLESS NICKEL INDUSTRY

In the fall and winter of 1994 a survey was conducted to establish what the electroless nickel industry presently is doing to treat its different waste streams and the cost of this treatment. This paper describes the results of this survey and summarizes the waste treatment practices and costs in the electroless nickel industry today.

Read

Electroless Nickel and the End-Of-Life Vehicle Directive

In 2000, the European Union began banning lead, mercury, cadmium, and hexavalent chromium from automobiles with their End-Of-Life Vehicle (ELV) directive. This paper will discuss this issue, as well as alternative technologies for lead and cadmium free coatings.

ReadThe information provided above is for general informational purposes only. Palm Technology makes no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, or suitability of the information for any purpose. Any reliance you place on such information is strictly at your own risk. Palm Technology disclaims all liability for any loss or damage arising from the use of or reliance on this information.