Fabrication Capabilities overview

Our company offers a full range of capabilities in both plastic and metal fabrication, utilizing state-of-the-art machinery and skilled craftsmanship to ensure precision, durability, and consistent quality in every project. From prototype development to full-scale production, we are equipped to handle a wide variety of industrial fabrication needs.

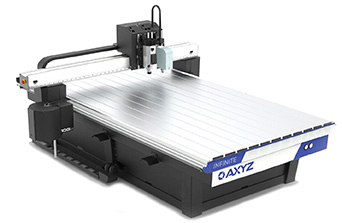

In plastic fabrication, we employ advanced AXYZ CNC routers (5x10 and 6x14) with Automatic Tool Changers (ATC), allowing for efficient, precise, and versatile cutting across a range of materials. These machines streamline complex tasks and ensure repeatable accuracy on both short-run and high-volume jobs.

Our plastic welding capabilities are supported by high-performance equipment, including a 13-ft Wegener butt welder, 10-ft Wegener bender, and a custom-built hydraulic channel fusion welder, all of which ensure strong, seamless joins. We also use Wegener extrusion and hot gas welders to meet a broad range of fabrication needs. All plastic welding operations are performed in accordance with German DVS plastic welding standards, guaranteeing consistency, quality, and long-lasting structural integrity.

Our metal fabrication capabilities are equally robust and versatile. We operate Miller MIG and TIG welders along with lathes, vertical and horizontal mills, and a Sabre CNC plasma cutter, enabling us to handle intricate designs, precision cuts, and tight tolerances. Key fabrication equipment includes a 90-ton Cincinnati press brake, a Scottsman ironworker for punching and shearing, and a Hydmech 10" x 18" miter bandsaw with bundle cutting capabilities for high-efficiency production.

For finishing, we operate a 1,400-cubic-foot paint booth capable of high-quality EPOXY painting, providing superior corrosion resistance and durability. Our facility also features a 20-foot-wide truck ramp with an 18-foot-wide by 16-foot-tall overhead door, allowing us to accommodate and ship the largest oversized loads permitted for highway transport. This ensures we can fabricate, assemble, and ship large-scale systems and components without compromise.

Efficient material handling and assembly are made possible by six overhead cranes, ranging from 5 to 20 tons, providing smooth movement of heavy components throughout the facility. By combining advanced technology, extensive in-house capabilities, and expert craftsmanship, we consistently deliver tailored fabrication solutions that exceed our clients' expectations in both plastic and metal applications.