Automated Surface Finishing Process Lines

Custom Plating and Anodizing Solutions for Complex Manufacturing Needs

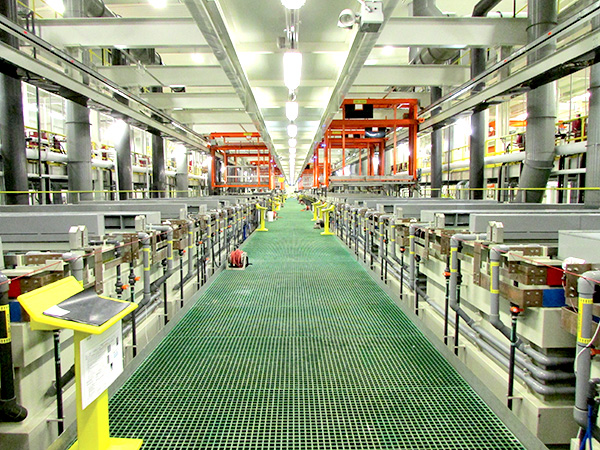

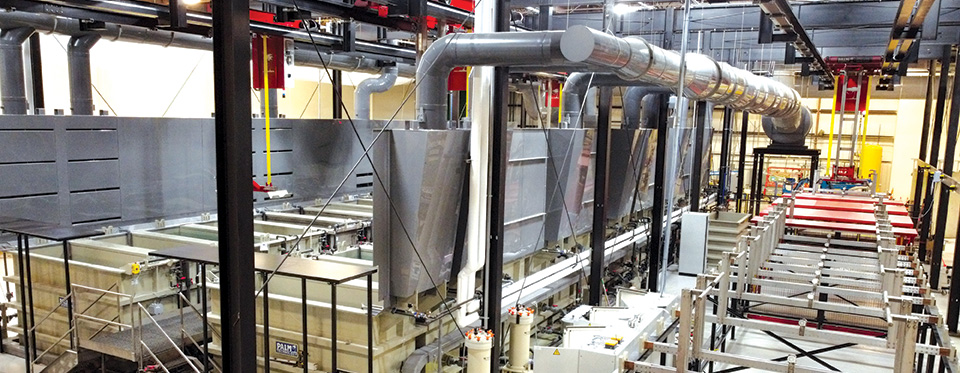

Palm Technology designs, fabricates, and installs fully automated plating lines engineered for long-term performance in the demanding conditions of modern plating environments. Our systems are built to endure harsh chemical exposure and high-throughput production, delivering consistent, repeatable results with minimal downtime.

We offer automatic plating lines equipped with overhead, side-arm, and rail rider hoists, all tailored to accommodate a wide variety of substrates, from machined and cast metals to precision molded plastics. Whether you're looking to plate barrels, racks, rotating fixtures, or baskets, our systems are designed to handle both decorative and functional plating applications. These solutions support a range of finishing processes across industries such as Aerospace, Automotive, Defense, Consumer Products, and Medical Devices, where consistency, durability, and compliance are critical.

Built with a modular approach, Palm's automated systems integrate all necessary utilities, including water, air, steam, cooling, and electrical cabling, into compact, easy-to-install units. This smart design not only accelerates installation but also reduces on-site labor requirements, ensures consistent system quality, and minimizes the time needed to reach full operational status. Our modular systems are scalable and adaptable, allowing for future upgrades and layout flexibility as your production needs evolve.

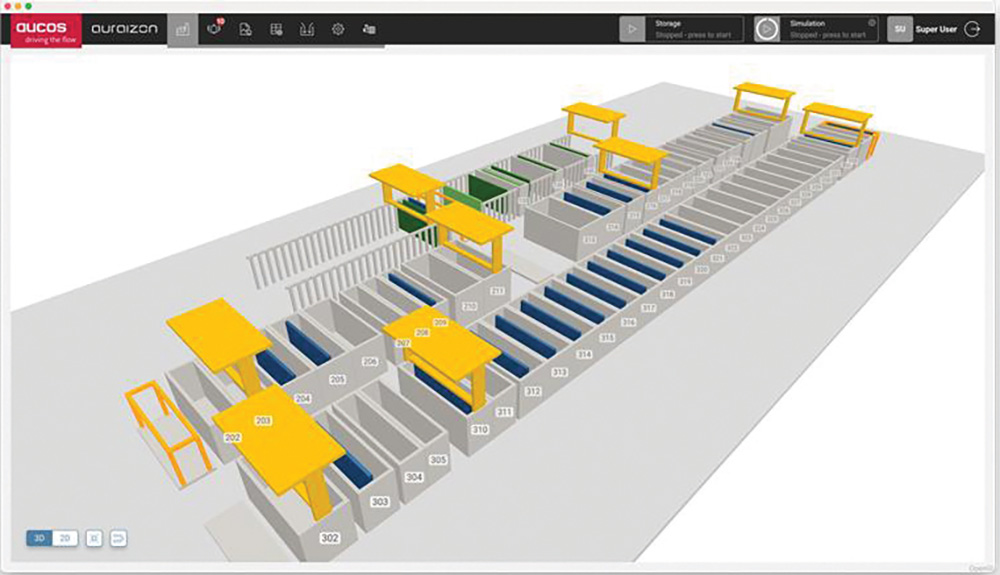

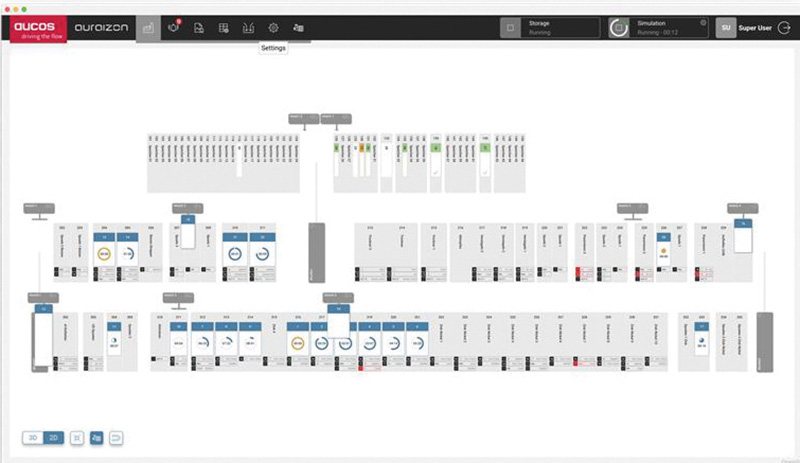

Aucos Automated Line Control Software

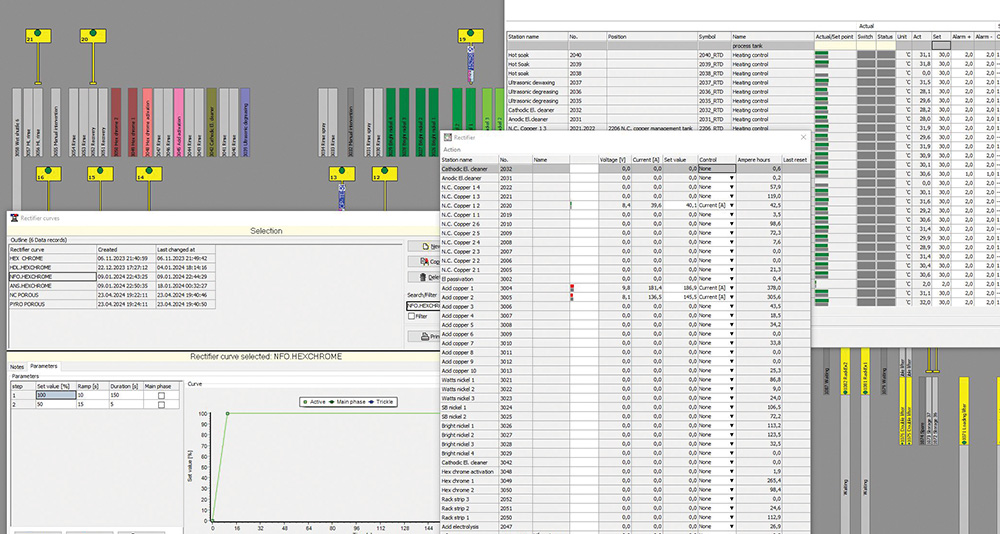

Automatic Control: Aucos control systems manage hoist movements, cycle times, and operating parameters on the process line, ensuring precise control and compliance with Nadcap and ISO standards.

Full Data Acquisition: The system offers comprehensive data acquisition and documentation capabilities, serving as a supervisory control and data acquisition system (SCADA), with integration for wastewater treatment and fume exhaust systems.

PC-Based Control: The PC-based control software handles multiple recipes simultaneously, allowing for efficient control, monitoring, recording, and alarms for individual tanks on the line.

PLC Controls: While the PC manages recipes, data acquisition, and hoist scheduling, the PLC executes all motion control, carrying out the PC’s commands and operating the hoists. It also manages line safety and operating other line control devices.

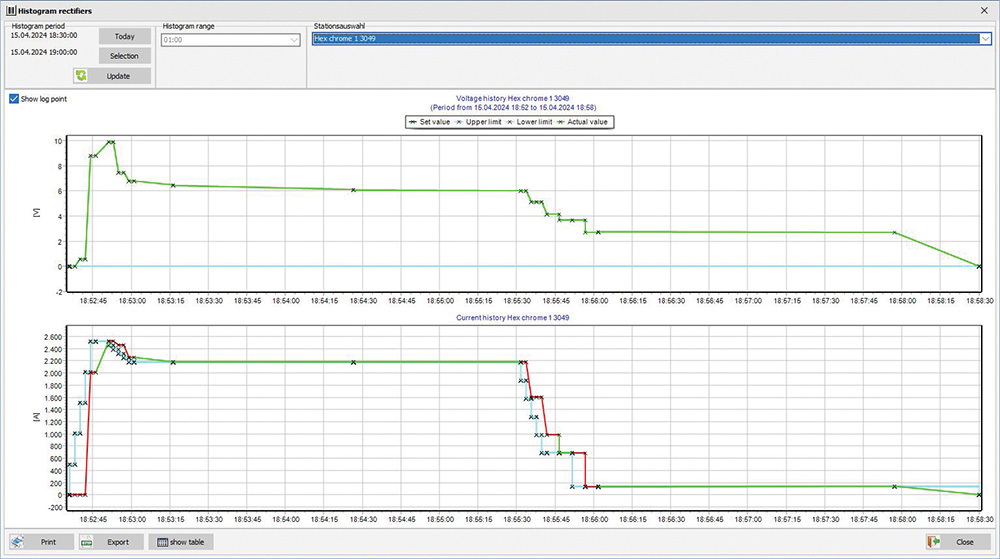

Hoist Operations: The system monitors and controls various functions, including overhead hoists, safety devices, load/unload stations, wet transfer shuttles, automatic covers, pumps, tank temperatures, levels, pH, conductivity, and rectifiers.

Fault Diagnostics: Fault diagnostics are displayed on the operator screen, indicating device malfunctions such as motor overloads, hoist faults, and emergency stop activation.

Software Features: Each load is defined by a unique number, with part recipes specifying process sequences, times, and parameters. Data acquisition records process conditions by load, including tank circulation, temperature, and rectifier output. Input to the automatic control system is password-protected, with customizable access levels for operators.

Reports: The software generates real-time information and customizable reports on production, operating conditions, and machine faults, meeting unique customer requirements for access and storage.