High-Performance Cathodes for Anodizing Systems

Customizable aluminum Anodizing cathode systems designed for superior surface finishing results.

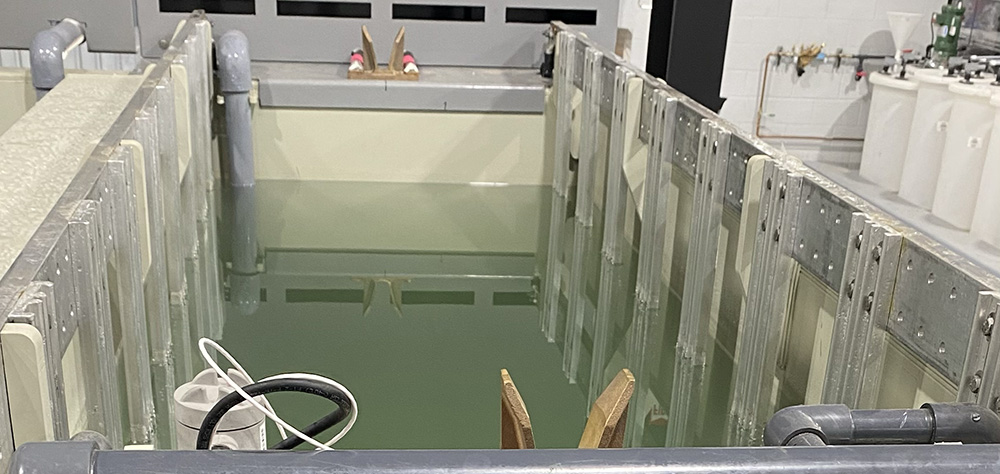

Anodizing is an electrochemical process that oxidizes a metal’s surface increasing hardness, protecting against corrosion and improving wear resistance. Cathode selection is critical to the process. Palm Technology offers high quality American made 6063t6 cathodes and header bars.

Aluminum cathodes outperform lead cathodes. Aluminum has 6- 7 times the conductivity of lead requiring less anodizing time at comparable current densities. Aluminum generates less heat reducing cooling requirements and there is no lead in the effluent.

Palm supplies high quality 6063t6 cathodes and headers bars that are extruded in America. 6063 aluminum is the alloy of choice for cathodes because it has a high conductivity and a low dissolution rate in acid. The dissolution rate during idle or “non-anodizing” periods is not measurable. The t6 temper is “full hard” for optimum conductivity.

An anode to cathode ratio for sulfuric acid anodizing of 3:1, 3 sq ft of part surface area for every sq ft of cathode, maintains a uniform oxide thickness on surfaces. Higher ratios can be used in the case of parts with blind holes.

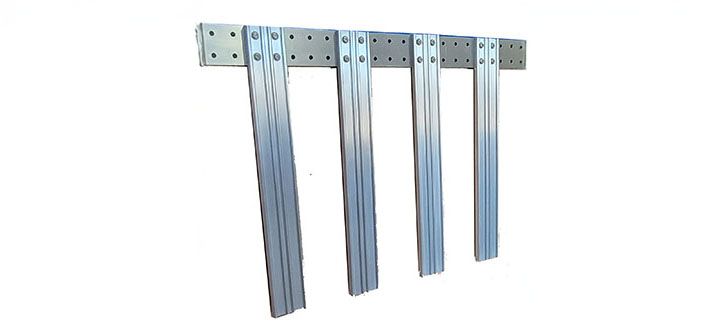

Palm offers a range of cathode lengths. The cathodes are pre punched and match the predrilled holes in the header bar. The cathodes are extruded with a profile increasing the cathode surface area. The increased surface area means more parts per load while maintaining the desired current density.

Palm cathodes are bolted to the header bar. The header bar is predrilled allowing the customer to adjust the cathode placement. We recommend and offer NO-OX-ID electrical contact grease guaranteeing good electrical contact between the cathode and header bar. Bolted cathodes provide the best contact between the header bar and cathodes. Cathodes are easily replaced and offer flexibility with regard to the number and placement. Cathodes can be added or removed depending on changes in the load profile.

Palm offers precut and predrilled header bars. Standard lengths are up to 12-ft in length. Longer lengths and non-drilled header bars are available upon request.

Palm’s cathodes are profiled and have 0.05 sq ft of area per inch of cathode. Cathodes are custom cut and punched in lengths up to 133” (11’ 1”). Flat or higher area profiles and longer lengths can be special ordered. Cathodes can be shipped unpunched.

In addition to supplying 6063t6 aluminum header bars and cathodes, Palm offers prepackaged 316L stainless steel mounting hardware and NO-OXID electrical contact grease.

Palm Technology maintains a working inventory of cathodes, header bars, fastener packets and contact grease. Orders typically ship within a week of receiving your PO and completing the paperwork. When you are ready to place your next order, call Palm Technology for all your anodizing needs.