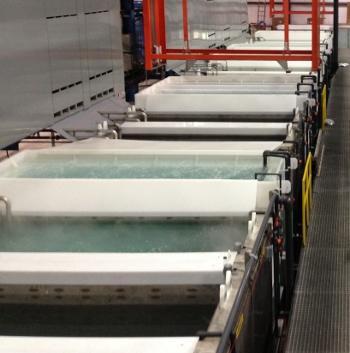

Automatic Acid Pickling Lines

Palm Technology engineers, fabricates and installs Automatic Acid Pickling Lines that are built to provide long term service in the harsh conditions found on a Cleaning Line. Palm builds lines to clean and coat low and high carbon steel, stainless steel and titanium for aerospace, automotive and industrial suppliers.

Palm has partnered with Aucos GmbH to provide a PC based automatic control system. PC controls offer the maximum flexibility for production lines with multiple cranes and extensive process control. They offer fixed or mixed cycle scheduling. Aucos is the global leader in automatic control systems for process lines.

Palm uses quality corrosion resistant materials to fabricate tanks, ducting, piping and structures based on the solutions, their temperatures and fume exposure. We finish tanks with a wide range of instrumentation. Palm tanks have customized guarding to prevent damage to sensors, heaters, and heat exchangers. Palm’s modular design minimizes installation time, provides the customer with process flexibility and allows for the line to be easily expanded.

We have the capability to build a single tank or an entire process line. Our tanks are spark tested at 20,000 volts and water tested to ensure even expansion and that they are defect free before they leave our facility.